Listeria: Developing a plant-based product? Don’t ignore these unexpected risks!

In this series of articles, NIZO Food Research Division Manager and FoodNavigator advisory panel member René Floris discusses some of the big issues in today’s food industry.

The recent Listeria monocytogenes outbreak in a vegan cheese produced in France shows all too clearly that this dangerous pathogen is not just an issue with animal-based products. While Listeria is generally associated with ready-to-eat foods such as dairy cheeses and deli meats, you cannot ignore the potential risk in your plant-based products – including from post-processing contamination. Karin Beekmann, Project Manager at NIZO, explains why including safety during the early stages of developing your plant-based product is key to mitigating the potential presence and growth of Listeria monocytogenes.

Listeria infection is very dangerous for susceptible people such as the elderly and immunocompromised, as well as pregnant women. If someone gets listeriosis, the mortality rate is as high as 20-30%. And while an outbreak can thus harm consumers, it may also impact the producer’s reputation, and cause food waste, high costs to address the problem, and liability issues.

Even quite low levels of initial contamination with Listeria can be a problem, especially if the bacterium can grow after the product has left the production facility: for instance, in the distribution chain or at the consumer’s home. So testing levels of bacteria is not sufficient to guarantee safety: you have to ensure that your product will not support growth of Listeria.

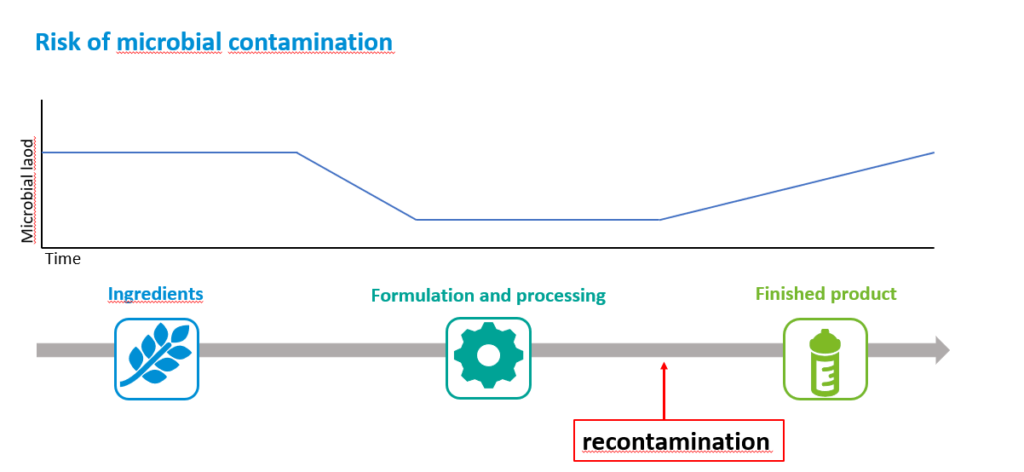

While Listeria monocytogenes is sensitive to heat, it is otherwise quite robust, and can survive – and grow! – even in quite salty or refrigerated foods, and sometimes even below 0°C. It is also widely present in our environment. This makes it an ‘ideal’ bacterium for post-processing contamination. So while your processing may kill the pathogen and ensure that a safe, sterile product comes off the line, your cheese, deli meat or plant analogue can get (re)contaminated with Listeria during slicing, packaging, etc. As ‘ready-to-eat’ foods are not reheated by the consumer, these bacteria are not killed off.

Listeria is often associated with animal-based products, and dairy and meat producers have long been aware of the risks and how to minimise them. However, plant-based products present some new challenges. While a meat or cheese analogue may resemble the original product with respect to taste and texture, its composition can be quite different. For example, dairy yoghurt is rarely associated with Listeria because of its low pH; vegan ‘yoghurt’, however, can have a higher pH, so the risk of Listeria growth may be present. If we look at cheeses, dairy cheeses are often fermented, which creates lactic acid that can help inhibit Listeria growth. But vegan cheeses are not generally fermented, and they do not develop lactic acid, so the conditions for Listeria growth are different. Therefore you cannot assume that the plant-based ‘equivalent’ of an animal-based product will have the same Listeria risks as the original version, and control of this pathogen must be ensured.

You do not want to get to the end of your product development process and discover you have a Listeria problem. You could then find yourself searching for solutions, reformulating ingredients, or modifying processing – all of which could impact your product’s characteristics, including taste, texture, and more.

Furthermore, all too often, new product development focuses on eliminating Listeria through processing, without considering the post-processing contamination. So besides making sure that the product is not contaminated, you need to develop ready-to-eat and plant-based products with a composition that inhibits Listeria growth.

Formulating a safe product is a complex puzzle, combining ingredients, components, processing, and more. There are very specific product characteristics that inhibit Listeria growth, for example, high acid levels (with a pH of under 4.4) or low water activity (aw under 0.92). You can also combine characteristics, such as a pH under 5.0 combined with a water activity (aw) under 0.94. However, adding ingredients such as lactic acid may not address the ‘healthy’, ‘clean label’ aspects that consumers expect from plant-based analogues.

A very useful technique to consider is fermentation, where lactic acid bacteria can produce organic acids, peptides, or antimicrobials. This inhibits bacterial growth in a way that consumers consider ‘natural’. But again, fermentation of plant-based products may not work in the same way as animal-based foods. The peptide nisin, for example, is known to inhibit Listeria growth in deli meats: but will it work for meat analogues as well? Plant-based products are a new world, and you can’t make any assumptions.

The first ‘tool’ is knowledge of microbiology and food development, which can give key direction and insight to focus on formulations that are likely to successfully inhibit Listeria growth. For example, NIZO has extensive experience with dairy products, and that knowledge helps us assess potential risks for plant-based dairy analogues by making the actual products, and then testing the different formulations in a high-throughput manner. In addition, our experience with pathogens, including Listeria, helps with any ready-to-eat food, including plant-based products.

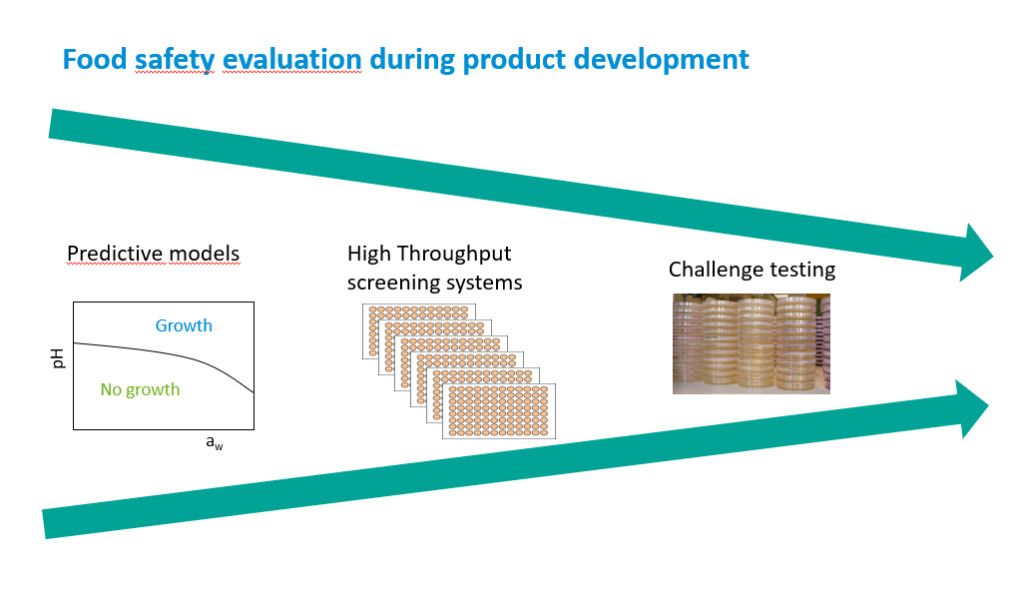

Predictive modelling is also very useful, and can be used at various stages of product development to map potential risks from Listeria (and other bacteria). Combined with high-throughput screening, true bacterial survival is quickly and effectively assessed throughout your product’s shelf life. For example, NIZO’s MicroCheese system can be used for high throughput screening in different dairy cheeses, and we have recently extended its use to plant-based cheese.

Because modelling and high-throughput screening techniques are fast and cost-effective, you can use them early to ensure you are including safety in your product design. Then you only have to take one or more potentially suitable compositions into the more expensive, full-blown challenge tests that are needed to validate the results.