meat alternatives

Table of Contents

In this series of articles, NIZO Food Research Division Manager and FoodNavigator advisory panel member René Floris discusses some of the big issues in today’s food industry.

The multi-billion-euro global meat-alternative market is expected to increase exponentially over the coming years. To get a share of that market, manufacturers have to find ways to meet consumers’ expectations – but it’s a complex mission. Steven Cornet, expert in protein technology at NIZO, discusses the search for ingredients and processes to take plant-protein-based products to the next level.

René Floris: What is driving the constant need to develop new meat replacement products?

Steven Cornet: Consumers’ expectations for meat and dairy replacements are high: they not only want a familiar taste and texture, they also want familiar handling and preparation. A ‘meat’ that browns when cooked, ‘shrimp’ that turn red… But they don’t want extra steps, such as hydrating an ingredient.

That means manufacturers must continue to develop new products that more closely mimic meat, fish, seafood, etc., in multiple aspects. And while there are many variables impacting the functionality and characteristics of a plant-based product, it should meet all of the expectations at the same time, which requires a holistic approach to development.

RF: What are the most important consumer expectations that manufacturers need to consider?

SC: Firstly, consumers are looking for sensory satisfaction: most people will not purchase a product that they do not enjoy eating. The sensory experience includes taste, texture, smell, appearance… While taste is often the first component to come to mind, it goes far beyond simply adding flavourings to impart a ‘meaty’ flavour. Plant proteins often have their own undesirable taste components, such as ‘beaniness’ or ‘grassiness’. You therefore have to find a way to mask or remove those flavours.

Everything from the raw materials to the processing can impact the taste of the end product, so careful selection from the start is key. At the seed or crop level, not only the species but the growing conditions, such as soil and climate, can impact flavour. For protein fractionation, you can choose between wet and dry methods: dry fractionation can result in stronger off-flavours, but wet fractionation is more expensive. Changing processing, to improve texture for example, can also alter flavour. It’s a delicate interplay that requires careful balancing.

RF: What are the challenges of improving texture?

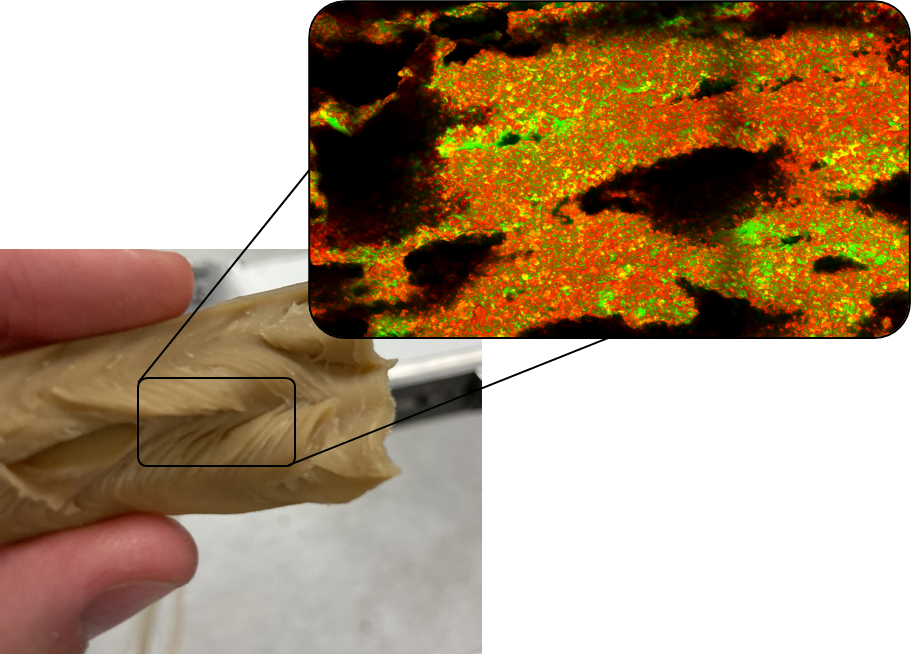

SC: The challenge depends on the type of product you want to make. Plant proteins, for example, don’t naturally have the fibrous structure that is so important to meat’s texture, but fibre can be created through processing. To create a steak alternative, you need to recreate the long fibres, as well as the distinctive bite and tenderness. You also need to match the thickness of a real steak. Developing a fish alternative, on the other hand, is quite different: here, you need moist, flaky layers.

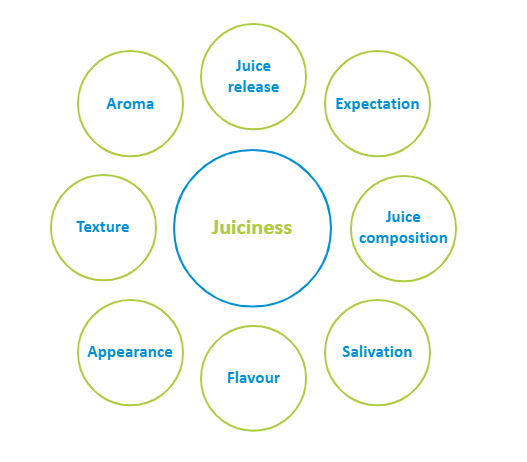

Texture comprises mouthfeel, consistency and appearance, which can be further divided into characteristics – such as the ‘juiciness’ typically associated with meat. The perception of juiciness can be affected by everything from juice release to juice composition. Furthermore, a product that smells and tastes ‘good’ stimulates saliva production: another element of juiciness. But there are also cross-modal effects between sensory attributes: a food that is tender can be perceived by the consumer as juicier.

Another challenge is to create more ‘clean label’ products: by eliminating methylcellulose, for example. This ingredient offers incredible functionality, such as emulsification, thickening, binding and firmness in hot applications. Finding natural ways to replace it is thus a big challenge for the industry.

RF: What technologies can manufacturers use to turn plant protein into a meat analogue?

SC: The most well-known and widely used is extrusion, which can be either at low or high moisture contents. With low moisture extrusion, a mixture containing plant-protein powder and water is passed through an extruder at high temperature and pressure. The expanded and rather spongy result is cut into small pieces that, after hydration, can be used in processed meat-like products, such as burgers and sausages, to give bite and texture. This technology has been used for half a century to create textured vegetable proteins (TVP). High moisture extrusion adds an additional, precisely controlled cooling step. This forms a fibrous or layered texture that more closely resembles whole muscle. Products such as chicken-replacement pieces are often made from high moisture meat analogues (HMMA). However, the thickness of the resulting product is limited by the dimensions of the cooling die, so it isn’t yet appropriate for creating steaks, for example.

RF: What new opportunities are available with low and high moisture extrusion?

SC: While we have come a long way, there is still a lot of untapped potential in terms of understanding the technology as well as the ingredients. New plant proteins, beyond the traditional soy and wheat, can offer novel functionalities. These also raise additional challenges, because they behave in different ways. Therefore, understanding the behaviour of proteins under such rather extreme conditions is key.

Adapting processes can also change structure and texture properties, and result in an improved taste or smell. A TVP that binds more water may contribute to juiciness, for example. But to modify taste and texture, you have to understand the impact of the process conditions on product properties.

RF: Are there other technologies that can create fibrous textures in plant-based products?

SC: Companies like NIZO have successfully developed longer plant-protein fibres, some of which are available on the market. These have functionalities that mimic certain physical characteristics of meat: for example, the fibres can be pulled apart like cooked chicken or pulled pork. But there are a lot of technical challenges to creating these types of products.

Promising methods include shear cell technology, which does not have the same product thickness limitations as extrusion. So you can make a fibrous slab of plant-based steak several centimetres thick. However, this is a batch-based process that is difficult to upscale to production levels.

3D food printing is also gaining a lot of attention: there are start-ups printing vegan meat substitutes that replicate meat muscle structure, and fish alternatives with a complex structure. Some of the products are already available in restaurants. But again, scaling up to the level of supermarket availability is proving a significant challenge.

RF: What should manufacturers keep in mind when developing plant-protein-based ingredients or products?

SC: With so many variables, it is important to take a scientific approach, and to create a planning path: from the choice of protein, to the processing, to the pilot plant and beyond. Expertise in all these areas is needed to filter the options and variables, so you can focus on the most promising.

Cases

© NIZO 2025 | Sitemap - Privacy Statement - Cookie Statement - Terms & Conditions

Website by: Online Marketing Agency