Developing flavours and products using fermentation

Recently, an interesting article was published in the Economist about the high diversity of yeast in cacao and coffee bean fermentations. The final products of both coffee and cacao are the result of fermentation, but most consumers are under the impression that both products are directly derived from the plant and are only industrially processed. They are not aware that the final product is a result of natural fermentation, which is essential to final flavour formation.

Both for cacao and coffee beans, fermentation is performed by a mixture of yeasts that produce a variety of flavours, whilst the most well-known product of yeast, alcohol, is either produced in low amounts or evaporates during the process. The interesting observation reported in the Economist article related to the high diversity of yeast identified in the cacao and coffee beans isolated from different locations. All these different yeast are expected to produce different flavour molecules. This allowed for the possibility to use cacao yeasts from Costa Rica in a cacao fermentation executed in the Dominican Republic, thereby adding specific flavours normally only present in Costa Rica cacao beans to cacao beans from the Dominican Republic.

All very exciting, but the dairy industry together with NIZO has done the same things for over 65 years now. Cheese production is one of the best known examples of fermentation. Using mixtures of bacteria results in a seemingly limitless range of flavours and they are responsible for the characteristic of – for instance – gouda, cheddar and Swiss-type cheeses. The addition of fungi results in very different types again such as brie or blue cheese, all to be found in supermarkets all over Europe and the US. All these cheeses show a high diversity in flavour and textures that are the result of using different organisms for the fermentation.

New food-grade strains to create new flavours are continuously isolated from nature. Interestingly, these strains do not have to be dairy-based. We at NIZO have shown that a food-grade bacterium from a plant can be evolved to grow on milk within a period of months. This can lead to an even larger variety of flavours that are the result of fermentation.

It is exciting to see that the technology, long used in the dairy industry, is finally translated to the coffee and chocolate industry. What can be seen as the next step is to use yeast isolated from coffee beans for cacao fermentation and vice versa. Although this may seem challenging at first from a scientific point of view, this is a much smaller step than the previously successfully conducted conversion of a plant bacterium to a dairy bacterium. This can lead to an even greater diversity of potential new flavours in the coffee and chocolate industry.

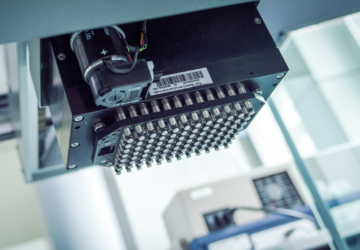

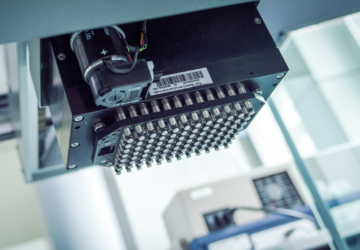

The biggest challenge in this will be to find out what type of flavours are of interest to a consumer, which is what marketing departments are looking for. To study thousands of new fermented products at NIZO we have developed a high throughput platform that screens thousands of fermentations simultaneously at a 200mg scale. In addition to the miniaturised process being an almost perfect copy of the industrial scale process, using cheese as a model in this case, it also proven to be able to detect specific flavour molecules and link this to the desired flavours.

It is clear that the food industry is at the verge of a breakthrough in finally leveraging the large natural diversity of bacteria and yeasts in nature. This will results in new flavours and therefore completely new products with unexpected, original and unique characteristics. We cannot think of a more exciting and brighter future.